Ukuqina okuphezulu kweTungsten Carbide Heading Cold Heading Dies / Cemented Carbide Heading Dies

1. Imveliso yaseTshayina ekhethekileyo ekuqhubeni nasekuveliseni, isatifikethi se-ISO.

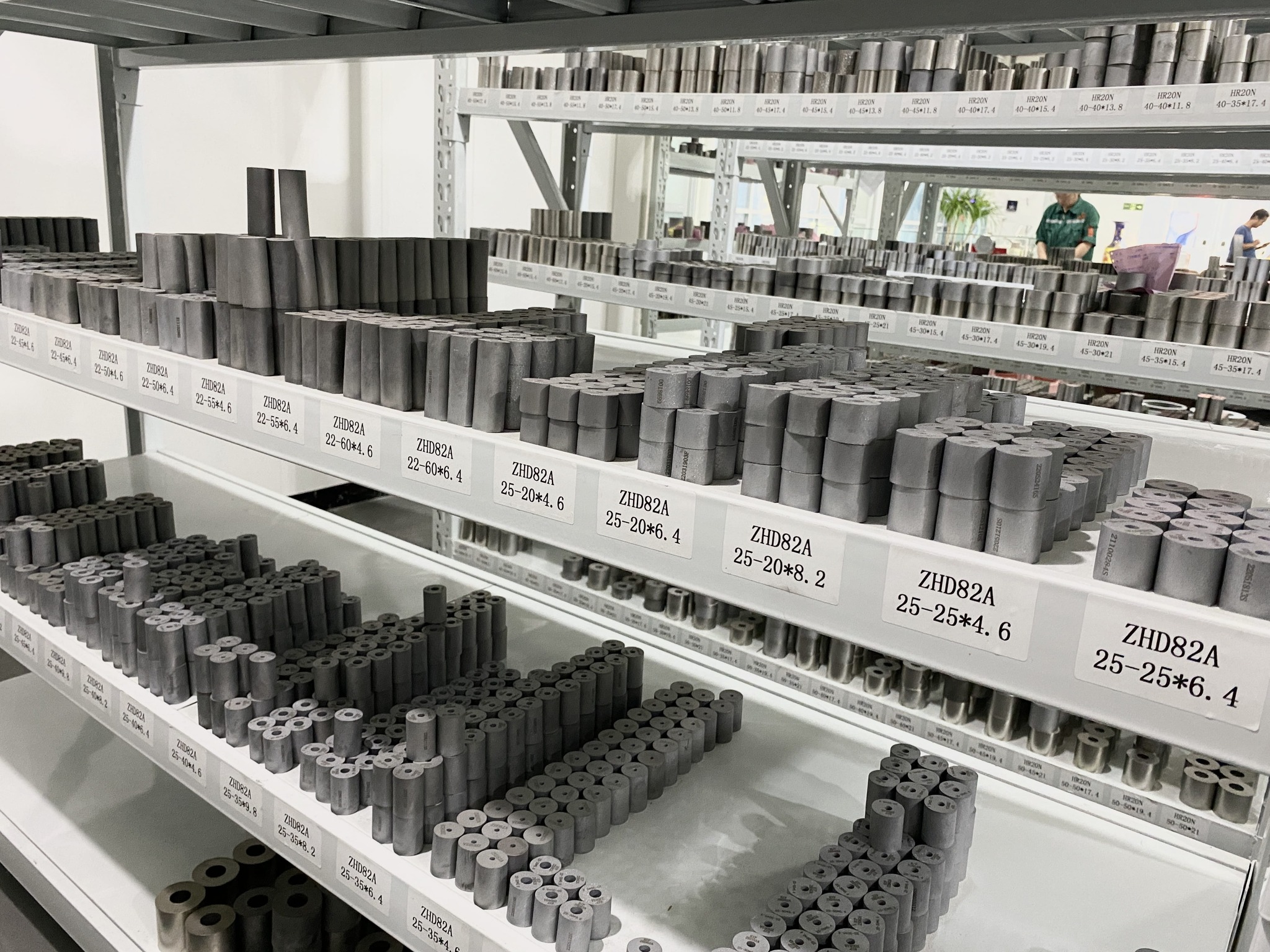

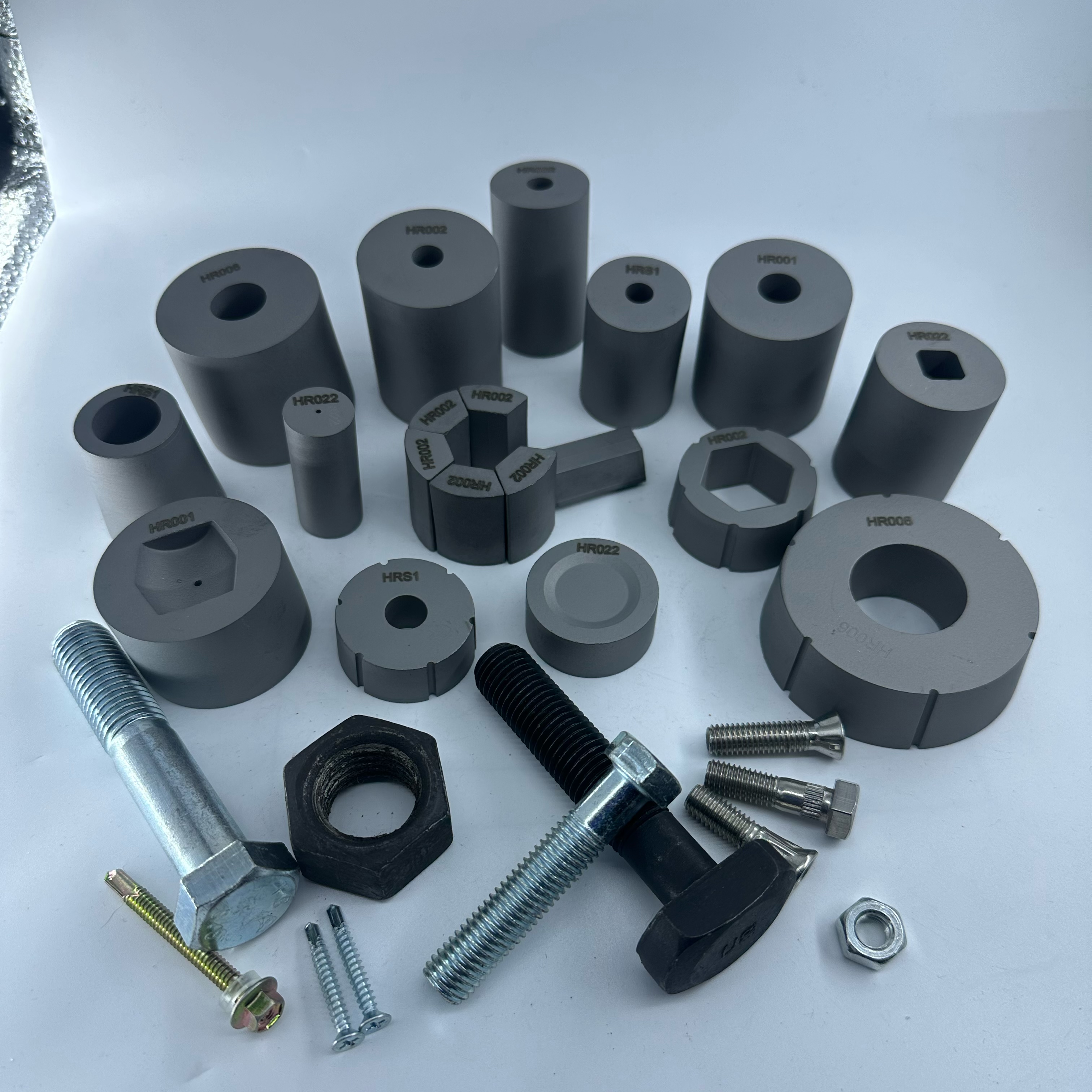

2. Iisayizi ezininzi kunye neentlobo ezikhoyo kwi-OEM.

3. Yenziwe nge-100% yezinto zokuqala ezikumgangatho ophezulu

4. Iqela lemveliso yobungcali, ukuhanjiswa ngokukhawuleza

5. Inkonzo yasimahla yokuthengisa emva kokuthengisa kunye nenkxaso yobugcisa

| ungsten Carbide Cold Forging/heading Dies | ||||

| Amabanga | Ukuxinana | TRS | Ukuqina | Ukusebenza kunye nesicelo esicetyiswayo |

| g/cm³ | MPa | HRA | ||

| YG11 | 14.4 | ≥3000 | 88.5 | Ukubumba okanye ukunyathela kufa ngenxa yomgubo wentsimbi kunye nomgubo ongeyontsimbi. |

| YG15 | 14 | ≥3400 | 87.5 | Ukwenza umzobo wokwenza umzobo uyafa ngeetyhubhu zentsimbi kunye neentonga phantsi komlinganiselo wokuxinezeleka okuphezulu;ukubetha, ukunyathela, ukwenza izixhobo phantsi koxinzelelo olukhulu. |

| YG20 | 13.5 | ≥3800 | 85.5 | Ukwenziwa kwesitampu seendawo zokubukela, iipleyiti zasentwasahlobo zezixhobo zomculo, iijagi zebhetri, iibhola zentsimbi ezinobungakanani obuncinci, izikrufu, izikrufu. |

| YG15C | 14 | ≥4000 | 86.5 | Kwimibhobho ye-oyile ye-cone, sika phakathi amatye athambileyo naqinile;ukukrazula kunye nokusika umthi omkhenkce, umthi othambileyo kunye neenkuni zokuqala. |

| YG16C | 13.9 | ≥3500 | 85.5 | Ukunyangwa kwempembelelo kuyafa. |

| YG18C | 13.7 | ≥3600 | 84.5 | Ukuchaneka kwempembelelo yokunyathela kuyafa, ukubunjwa kwe-hot-press kuyafa kunye neerola. |

| YG20C | 13.5 | ≥3800 | 83.5 | Ifa ngenxa yokunganyangeki okanye ukumelana nempembelelo kwisicelo. |

| YG22C | 13.3 | ≥4000 | 83 | Ukwenziwa kwamandongomane kuyafa kwaye ukuxhathisa kwempembelelo ephezulu kuyafa. |

| YG25C | 13.1 | ≥4250 | 82.5 | Intloko yebholithi engatyiwayo iyafa kunye neerola. |

Ungqamaniso lweMathiriyeli→Ukugaya iBhola eManzi→I-WC exubeneyo kunye naMandla eCobalt→Ukucinezela→Iziko zokuJonga zeHIP→Ukuchongwa kweQC→Ukupakisha

- Yonke inkqubo yokuvelisa inomntu okhethekileyo wokuvavanya ukuqinisekisa umgangatho

- Yiba neenjineli eziqeqeshiweyo ukujonga umgangatho

- Zonke iimveliso ziphantsi kolawulo olungqongqo lwenkqubo esekelwe kwi-ISO9001:2008

1. Ingxelo kwiiyure ezingama-48;

2. Unxibelelwano oluhle lwesiNgesi;

3. Ingcebiso yobuchwephesha kwimveliso;

4. Uqeqesho olulungileyo lomntu othengisa ngaphandle;

5. Abanobuchule kwi-tungsten carbide bathengise;

6. Emva kwenkonzo yokuthengisa.

Siya kuzisa umthwalo oveliswe ngobunzima phakathi kweentsuku ezingama-30 emva kwentlawulo ephantsi, ngelixa, ukuba kukho izicelo ze-soecific ngexesha lokuhanjiswa.Sinokwenza utshintsho ngokwesicelo sabathengi, ngoko ke ixesha elifutshane lokuhambisa lifumaneka ngokupheleleyo.

Ngokuqhelekileyo i-30% T / T kwangaphambili, ibhalansi ye-70% ngokumelene nekopi ye-B / L.Kananjalo inokutshintsha ngokwesicelo sabathengi.

Senza amacandelo ngokweemilo ezahlukeneyo kunye nobukhulu ukuze angqinelane neemfuno zabathengi bethu ngokuthe ngqo, nokuba bafuna iibhloko okanye amaphepha, iisilinda, iibheringi, iingcebiso okanye amazinyo.