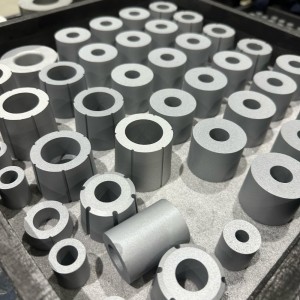

Ukuqina okuphezulu kweTungsten Carbide Heading Cold Heading Dies / Cemented Carbide Heading Dies

1. Imveliso yaseTshayina ekhethekileyo ekuqhubeni nasekuveliseni, isatifikethi se-ISO.

2. Iisayizi ezininzi kunye neentlobo ezikhoyo kwi-OEM.

3. Yenziwe nge-100% yezinto zokuqala ezikumgangatho ophezulu

4. Iqela lemveliso yobungcali, ukuhanjiswa ngokukhawuleza

5. Inkonzo yasimahla yokuthengisa emva kokuthengisa kunye nenkxaso yobugcisa

I-1.Iipilisi ze-carbide ze-Cemented zisetyenziswa ngokubanzi kwi-heading heading dies and punching dies

ukwenza amandongomane, iibholiti kunye nezinye iimveliso ezininzi.

2.Ibakala GT55/YG25C yeyona nto isetyenziswa kakhulu ekwenzeni iipeliti zecarbide.

Ineempawu ezibalaseleyo ezikhokelela ekusebenzeni kakuhle kunye nexesha elide lenkonzo.

3.Ngaphandle kobukhulu obuqhelekileyo, ubungakanani obungaqhelekanga beepellets ze-carbide

inokuveliswa ngokweemfuno zomthengi.

4.Zonke iipellets ze-carbide zihlolwe ngokungqongqo nge-ultrasonic flaw detector

ukuphepha ezinemingxuma yokuvuthela okanye iintanda eziphuma kumzi-mveliso.

| Tungsten Carbide Cold Forging/heading Dies | ||||

| Amabanga | Ukuxinana | TRS | Ukuqina | Ukusebenza kunye nesicelo esicetyiswayo |

| g/cm³ | MPa | HRA | ||

| YG11 | 14.4 | ≥3000 | 88.5 | Ukubumba okanye ukunyathela kufa ngenxa yomgubo wentsimbi kunye nomgubo ongeyontsimbi. |

| YG15 | 14 | ≥3400 | 87.5 | Ukwenza umzobo wokwenza umzobo uyafa ngeetyhubhu zentsimbi kunye neentonga phantsi komlinganiselo wokuxinezeleka okuphezulu;ukubetha, ukunyathela, ukwenza izixhobo phantsi koxinzelelo olukhulu. |

| YG20 | 13.5 | ≥3800 | 85.5 | Ukwenziwa kwesitampu seendawo zokubukela, iipleyiti zasentwasahlobo zezixhobo zomculo, iijagi zebhetri, iibhola zentsimbi ezinobungakanani obuncinci, izikrufu, izikrufu. |

| YG15C | 14 | ≥4000 | 86.5 | Kwimibhobho ye-oyile ye-cone, sika phakathi amatye athambileyo naqinile;ukukrazula kunye nokusika umthi omkhenkce, umthi othambileyo kunye neenkuni zokuqala. |

| YG16C | 13.9 | ≥3500 | 85.5 | Ukunyangwa kwempembelelo kuyafa. |

| YG18C | 13.7 | ≥3600 | 84.5 | Ukuchaneka kwempembelelo yokunyathela kuyafa, ukubunjwa kwe-hot-press kuyafa kunye neerola. |

| YG20C | 13.5 | ≥3800 | 83.5 | Ifa ngenxa yokunganyangeki okanye ukumelana nempembelelo kwisicelo. |

| YG22C | 13.3 | ≥4000 | 83 | Ukwenziwa kwamandongomane kuyafa kwaye ukuxhathisa kwempembelelo ephezulu kuyafa. |

| YG25C | 13.1 | ≥4250 | 82.5 | Intloko yebholithi engatyiwayo iyafa kunye neerola. |

Ungqamaniso lweMathiriyeli→Ukugaya iBhola eManzi→I-WC exubeneyo kunye naMandla eCobalt→Ukucinezela→Iziko zokuJonga zeHIP→Ukuchongwa kweQC→Ukupakisha

Tungsten Carbide Cold Forging Die

Ngaphambi kokuveliswa kobuninzi, kufuneka senze uvavanyo olucinezelayo kunye ne-sintering, kwaye sijonga ukubonakala kunye nobukhulu, ubuninzi kunye nobunzima beesampuli kunye ne-micrometer, i-microscope ye-Metallurgical, i-densitometer njl. imvelisoZonke iimveliso kufuneka zihlolwe ngokungqongqo yi-QC yethu.

Iipelisi ze-carbide ezifakwe ngesamente zisetyenziswa ngokubanzi kwintloko ebandayo yokufa kunye nokufa kwenqindi

ukwenza amandongomane, izikrufu, iibholiti, iinkonkxa kunye nezinye iimveliso ezininzi.

1. Ukumelana nokugqwesa okulungileyo.

2. Ukuchaneka okuphezulu.

3. Ra0.2 uburhabaxa bomphezulu.

4. Yenziwe ukusuka kwi-100% ye-virgin ekrwada.

5. Iveliswe ngaphaya kwenkqubo kunye nokuhlolwa kokugqibela.

6. Ikhono lokuvelisa elizinzileyo neliqhubekayo.

1. Ingxelo kwiiyure ezingama-48;

2. Unxibelelwano oluhle lwesiNgesi;

3. Ingcebiso yobuchwephesha kwimveliso;

4. Uqeqesho olulungileyo lomntu othengisa ngaphandle;

5. Abanobuchule kwi-tungsten carbide bathengise;

6. Emva kwenkonzo yokuthengisa.

Siya kuzisa umthwalo oveliswe ngobunzima phakathi kweentsuku ezingama-30 emva kwentlawulo ephantsi, ngelixa, ukuba kukho izicelo ze-soecific ngexesha lokuhanjiswa.Sinokwenza utshintsho ngokwesicelo sabathengi, ngoko ke ixesha elifutshane lokuhambisa lifumaneka ngokupheleleyo.

Ngokuqhelekileyo i-30% T / T kwangaphambili, ibhalansi 70% TT ngaphambi kokunikezelwa.Kananjalo inokutshintsha ngokwesicelo sabathengi.

Senza amacandelo ngokweemilo ezahlukeneyo kunye nobukhulu ukuze angqinelane neemfuno zabathengi bethu ngokuthe ngqo, nokuba bafuna iibhloko okanye amaphepha, iisilinda, iibheringi, iingcebiso okanye amazinyo.