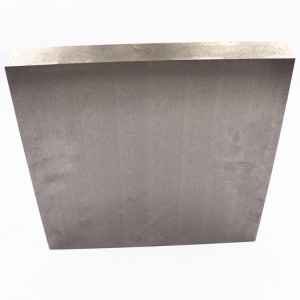

I-100% yeVirgin Material yeHip Tungsten Carbide iibhloko zeTungsten Carbide Parts Carbide Plate

Ukuchaneka kokusila ipleyiti ye-carbide ephezulu yokusebenza kwe-tungsten yentsimbi yentsimbi yokwazisa

1. Ukucoceka kwezinto eziluhlaza kufikelela ngaphezu kwe-99.95%, umxholo wokungcola uphantsi, kwaye iimpawu ezibonakalayo zebhodi zizinzile;

2. Ukusebenzisa iteknoloji yokumisa i-spray, izinto eziphathekayo zikhuselwe yi-ammonia ecocekileyo phantsi kweemeko ezitywinwe ngokupheleleyo, ezinciphisa ngokufanelekileyo ithuba lokufumana i-oxygen ngexesha lokulungiselela umxube.Ubunyulu bungcono kwaye izinto eziphathekayo akulula ukuba zibe mdaka;

3. Ubuninzi bebhodi iyunifomu: icinezelwe nge-300Mpa isostatic press, ephelisa ngokufanelekileyo ukwenzeka kweziphene ezicinezelayo, kunye nobuninzi bebhodi engenanto ifana kakhulu: 4. Ubuninzi bebhodi bugqwesileyo, kwaye iimpawu zamandla kunye nobunzima zihlangabezana nemigangatho: iteknoloji ephantsi yoxinzelelo lwe-sintering isetyenziselwa ukwenza ibhodi I-pores yangaphakathi iyacinywa ngokufanelekileyo, kunye nomgangatho.

uzinzile ngakumbi.

Isakhiwo se-metallographic yangaphakathi yeplate sinokuphuculwa kwaye uxinzelelo lwangaphakathi lungancitshiswa kakhulu, lugweme ngokufanelekileyo amathuba okuqhekeka kwiplate ngexesha lokusika kunye nokuqulunqa.5. Sebenzisa iteknoloji yonyango ye-cryogenic;

[Uluhlu losetyenziso lwepleyiti ye-carbide kunye nepleyiti yentsimbi ye-tungsten]:

Ukulungele ukwenza i-cast iron rolling kunye ne-high-nickel-chromium roll yokugqoka kunye neemela zokubumba;

Ilungele ukwenza iipleyiti zokothula, isitampu siyafa, i-punch dies, i-electronic progressive dies kunye nezinye izitampu ziyafa, njl.

Ukwenziwa ngokwezifiso okungaqhelekanga, ukulungelelaniswa okukhethekileyo.Imifanekiso kunye neekowuteshini ze-intanethi zenzelwe ireferensi kuphela.Amaxabiso anokwahluka ngokuxhomekeke kwiinkcukacha ezithile, imathiriyeli ekrwada, iindleko, kunye nobungakanani beodolo.

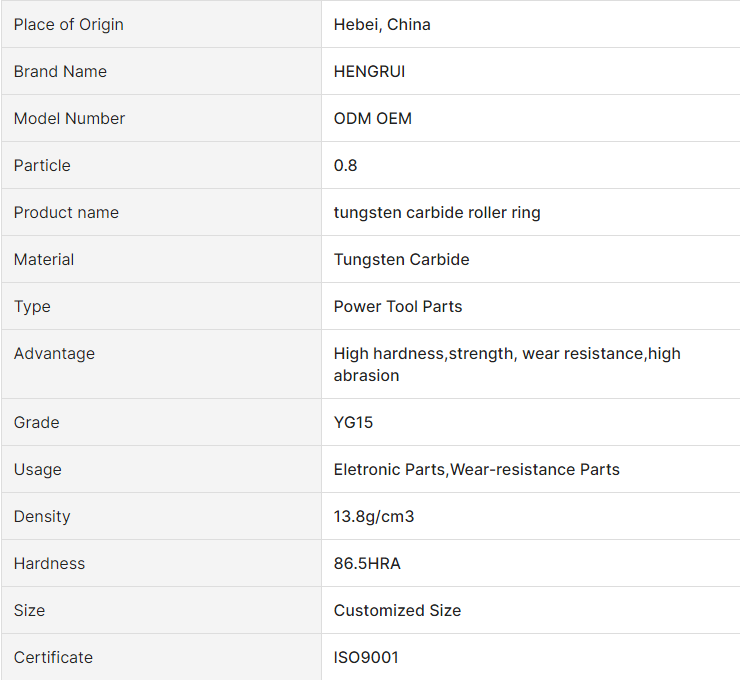

AmaBanga ahlukeneyo oKhetho:

| Tungsten Carbide Cold Forging/heading Dies | |||||

| Amabanga | Ukuxinana | TRS | Ukuqina | Ukusebenza kunye nesicelo esicetyiswayo | |

| g/cm³ | MPa | HRA | |||

| YG11 | 14.4 | ≥3000 | 88.5 | Ukubumba okanye ukunyathela kufa ngenxa yomgubo wentsimbi kunye nomgubo ongeyontsimbi. | |

| YG15 | 14 | ≥3400 | 87.5 | Ukwenza umzobo wokwenza umzobo uyafa ngeetyhubhu zentsimbi kunye neentonga phantsi komlinganiselo wokuxinezeleka okuphezulu;ukubetha, ukunyathela, ukwenza izixhobo phantsi koxinzelelo olukhulu. | |

| YG20 | 13.5 | ≥3800 | 85.5 | Ukwenziwa kwesitampu seendawo zokubukela, iipleyiti zasentwasahlobo zezixhobo zomculo, iijagi zebhetri, iibhola zentsimbi ezinobungakanani obuncinci, izikrufu, izikrufu. | |

| YG15C | 14 | ≥4000 | 86.5 | Ukwenzela i-oyile cone drill bits, ukusika amatye athambileyo kunye naqinileyo; ukukrazula kunye nokusika umthi omkhenkce, umthi othambileyo kunye neenkuni zokuqala. | |

| YG16C | 13.9 | ≥3500 | 85.5 | Ukunyangwa kwempembelelo kuyafa. | |

| YG18C | 13.7 | ≥3600 | 84.5 | Ukuchaneka kwempembelelo yokunyathela kuyafa, ukubunjwa kwe-hot-press kuyafa kunye neerola. | |

| YG20C | 13.5 | ≥3800 | 83.5 | Ifa ngenxa yokunganyangeki okanye ukumelana nempembelelo kwisicelo. | |

| YG22C | 13.3 | ≥4000 | 83 | Ukwenziwa kwamandongomane kuyafa kwaye ukuxhathisa kwempembelelo ephezulu kuyafa. | |

| YG25C | 13.1 | ≥4250 | 82.5 | Intloko yebholithi engatyiwayo iyafa kunye neerola. | |

Ungqamaniso lweMathiriyeli→Ukugaya iBhola eManzi→I-WC exubeneyo kunye naMandla eCobalt→Ukucinezela→Iziko zokuJonga zeHIP→Ukuchongwa kweQC→Ukupakisha

Zonke iimveliso kufuneka zihlolwe ngokungqongqo nge-ultrasonic kwaye kuphela ezo ezingenayo nayiphi na ingozi efana ne-aspore inokuthunyelwa ngaphandle.

Sineqela elinamandla nelifundisiweyo eliquka: Iqela loLawulo abantu abali-10,Iqela loPhando abantu aba-5, abasebenzi abanamava abangama-77. Abaphathi bezentengiso abali-10.

Samkela ulawulo lwenkqubo ye-7S-Seiri, Seiton,Seiso, Seiketsu,Shitsuke,Ukhuseleko,Isantya,Ukugcina.Lonke uluhlu lweemveliso luphethe injineli yokuthengisa eyingcali

Ngokuqhelekileyo i-30% T / T kwangaphambili, ibhalansi ye-70% ngokumelene nekopi ye-B / L.Kananjalo inokutshintsha ngokwesicelo sabathengi.

Senza amacandelo ngokweemilo ezahlukeneyo kunye nobukhulu ukuze angqinelane neemfuno zabathengi bethu ngokuthe ngqo, nokuba bafuna iibhloko okanye amaphepha, iisilinda, iibheringi, iingcebiso okanye amazinyo.