I-tungsten carbide(WC) yikhompawundi eyenziwe nge-tungsten yentsimbi ephikisayo kunye nekhabhoni engeyiyo eyentsimbi, eneempawu zokuxinana okuphezulu, indawo yokunyibilika ephezulu, ukomelela okuphezulu, ukuqina okuphezulu, ukumelana nobushushu obuphezulu, ukumelana nomhlwa, ukuxhathisa ukunxiba kunye nokuhamba kakuhle kombane kunye ne-thermal. , ngoko yinto efanelekileyo yesixhobo se-carbide.

Nangona kunjalo, ngenxa yengxaki ye-brittleness kunye nokuqina okungahambi kakuhle komgubo we-WC olula, kudla ngokuyimfuneko ukongeza inani elifanelekileyo le-binder njenge-cobalt (Co), i-nickel (Ni), i-chromium (i-Cr), i-molybdenum (i-Mo), i-titanium ( Ti), ubhedu (Cu) kunye nezinye izinto xa usenza izixhobo ze-carbide eziphezulu zokusebenza.

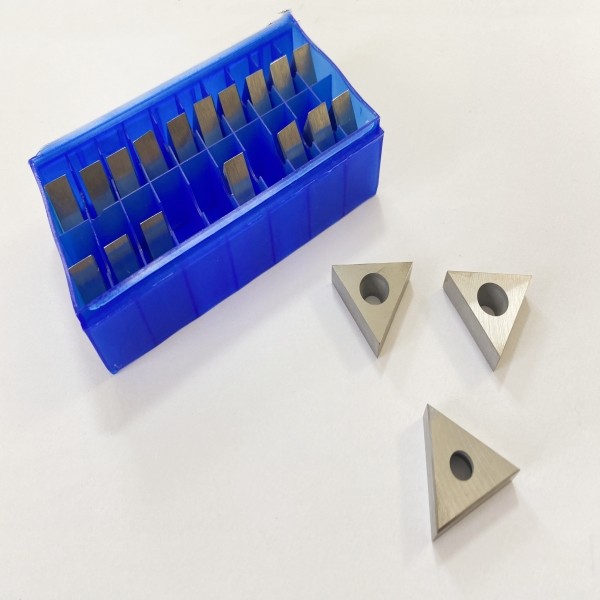

Ngokukodwa, kunye ne-WC powder njengesigaba esinzima kunye ne-Co njengesigaba se-binder sifanelekile ngakumbi kwizixhobo zokusika.Ine-conductivity enhle ye-thermal, ekulungele ukusika ukuchithwa kobushushu ukusuka kwincam yesixhobo, ukunciphisa iqondo lokushisa kwi-tip kunye nokuphepha ukugqithisa kunye nokuthambisa isicatshulwa sesixhobo;inamandla aphezulu okuguquguquka kunye nokuqina kwempembelelo, enokunciphisa ngokufanelekileyo ithuba lokuqhawula xa usika;inokumelana okugqwesileyo kokusika (ikude kakhulu kunentsimbi yesantya esiphezulu), kwaye inokugaya umgca obukhali.

i-carbide blade eyenziwe ngesamentenge-WC powder njengesigaba esinzima kunye ne-Ni njengesigaba sokudibanisa sifaneleke ngakumbi kwiindawo ezixhathisa ukubola.Ukuxhathisa kwayo kwe-corrosion kunamandla kunoko kwe-tungsten kunye ne-cobalt carbide izixhobo, okwenza ukuba ifaneleke usetyenziso kwiindawo ezinemithombo eyahlukeneyo ye-corrosive.Ukongeza, i-WC-Ni ye-cemented carbide seals nayo ifanelekile kwizicelo kwiqondo lokushisa eliphantsi, ubushushu obuphezulu, i-vacuum kunye noxinzelelo oluphezulu.

Iqulunqwe yi-WC, i-TiC kunye ne-Co ineempawu zobunzima obuphezulu, ukuxhathisa ubushushu obuhle, amandla acinezelayo aphezulu, ukuxhathisa okulungileyo kwe-oxidation, ukungahambi kakuhle kwe-thermal kunye nokunye, okulungele ukusetyenzwa kwentsimbi.

Kufuneka kuqatshelwe ukuba izikhombisi ezithile zomzimba zei-alloy eqinileiya kutshintsha ngomlinganiselo owahlukileyo wemathiriyeli ekrwada.Ukuba umaleko okanye iileya ezininzi ze-carbide, i-carbide kunye nezinye iikhompawundi ezilukhuni ezinqabileyo zifafazwa kumphezulu we-alloy eqinile, ukuxhathisa okuphezulu kunye nokuqina okuphezulu kwe-alloy kuya kuhambelana ngakumbi, ngoko kulungeleka ngakumbi ukusika ngesantya esiphezulu. .

Ixesha lokuposa: May-02-2023