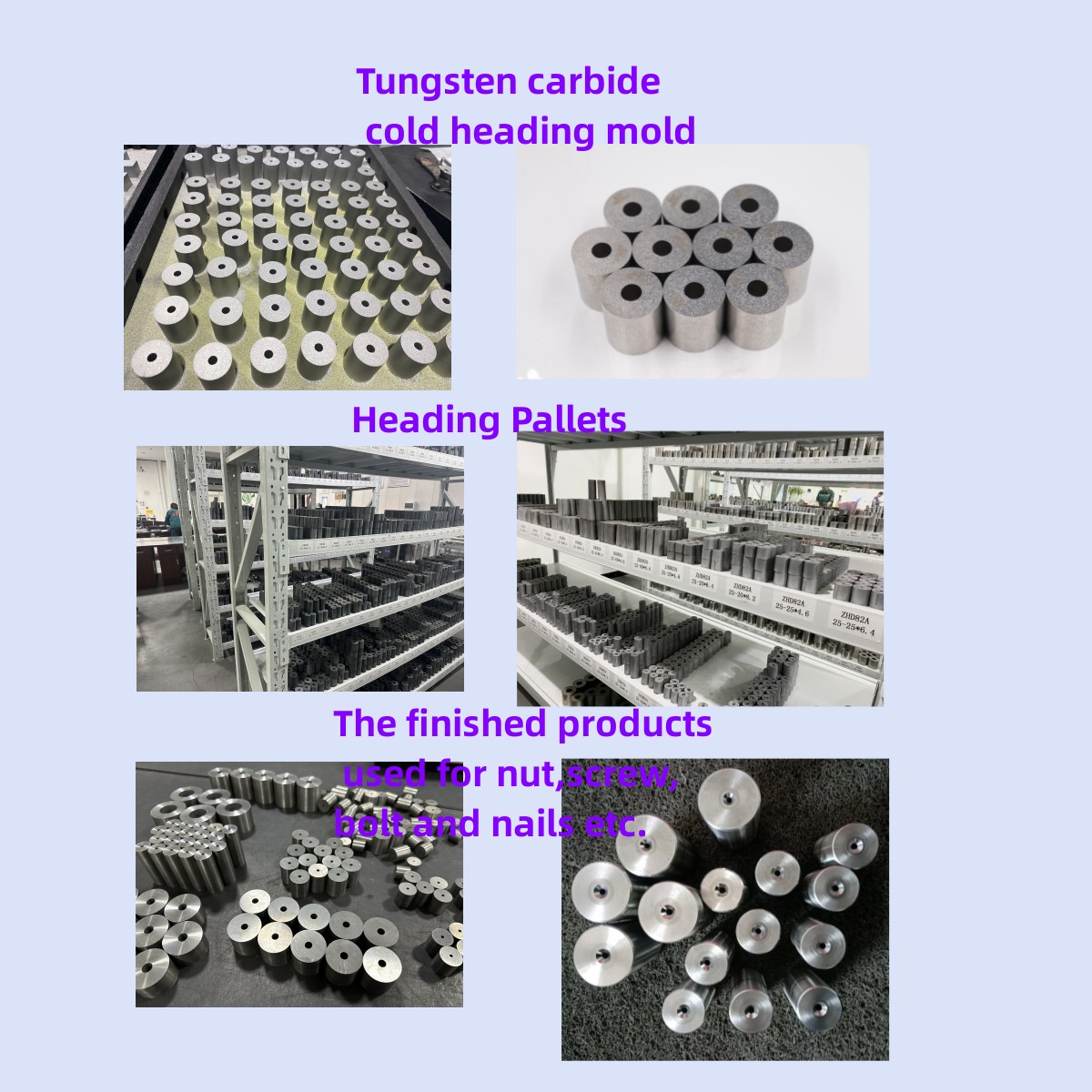

Isihloko esibandayo se-carbide esinesamente siyafa sidlala indima ebaluleke kakhulu kwinkqubo yokwenziwa kweendawo ezibandayo.Ngokufa kwesihloko esibandayo se-carbide, izixhobo zetsimbi zinokukhubazeka zibe ziimilo ezahlukeneyo, ezinje ngeebholiti, amandongomane, izikrufu, izikhonkwane, amatyathanga, njl. njl. amandla aphezulu kunye nomgangatho ophezulu.Ukwengeza,i-tungsten carbide isihloko esibandayo siyafazisetyenziswa kakhulu kwiinkalo ezahlukeneyo ezifana noomatshini, iimoto, i-aerospace, i-electronics, njl., kubandakanywa nokuveliswa kwenkqubo yokuhanjiswa kweenxalenye kunye nezibophelelo ezahlukeneyo, kuba indlela yesihloko esibandayo inokuvelisa iMisonto echanekileyo yangaphakathi nangaphandle kunye nezinye iijometri.Ehlabathini lonke, amazwe ahlukeneyo ahlala ekhuthaza ukutsha kweteknoloji kwindawo ebandayoiipaliti zesihlokoishishini lokungunda, ukuphucula ukusebenza kakuhle kwemveliso kunye nomgangatho wemveliso, kunye nokuphucula ngokufanelekileyo inqanaba lemveliso yoshishino.

tungsten Carbide moldsukudlala indima ebaluleke kakhulu kwiisiqhoboshiishishini.Njengezinto ezinobunzima obuphezulu, amandla aphezulu, ukuqina okuphezulu kunye nokumelana nokugqoka okuphezulu, kunokuqinisekisa ukuba iimveliso ze-fastener zinokuba nomgangatho ozinzile kunye nokusebenza ngexesha lenkqubo yokuvelisa.Inzuzo ye-tungsten carbide molds kukuba inokucutshungulwa ngokuchanekileyo ngezixhobo ezifana ne-molds kunye neetemplates zokudlula ezininzi, ukwenzela ukuba ukubonakala kunye nobukhulu be-fasteners kunokuhambelana.Ngophuhliso loshishino lwanamhlanje, ishishini elikhawulezayo lineemfuno eziphezulu neziphezulu zokuchaneka kwemveliso kunye nomgangatho.Oku kufuna ukuba isikhunta kufuneka sibe neempawu zokuchaneka okuphezulu, ukumelana nokunxiba okuphezulu, kunye nokuqina okuphezulu ukuze kuhlangatyezwane neemfuno zokuvelisa ezintsonkothileyo kwishishini le-fastener.Ukongeza, imibumbo ye-carbide enesamente nayo inokumelana ne-corrosion elungileyo, uzinzo lwe-thermal kunye neepropathi zoomatshini, kwaye inokumelana neemeko ezingqongileyo zokwenziwa kwemveliso kunye neemeko zokusetyenzwa, ukuqinisekisa ukuba iimveliso ze-fastener aziyi kuba neengxaki zomgangatho ngenxa yokuphambuka kokulungiswa kunye neminye imiba.Ukushwankathela, ukubunjwa kwe-carbide ene-cemented kunenzuzo yokuchaneka okuphezulu, ukuchasana nokunxiba okuphezulu, ukuqina okuphezulu, ukuxhathisa kwe-corrosion, ukuzinza kwe-thermal, njl., kwaye idlala indima ebaluleke kakhulu kwinkqubo yokuvelisa i-fastener industry.

Ixesha lokuposa: May-21-2023