Ukutshisa ngasemva kubhekiselele kwindlela yokuphinda ujike ukugoba iimveliso ezigogekileyo, ezingeniswayo, iimveliso ezikhutshiweyo kunye.iimveliso ze-tungsten carbidengeepores ezigqithisileyo.(1) Ukubuyisela umva kweemveliso ezingenayo kunye ne-decarburized.I-Carburizing kunye nokutshisa umva ngokuqhelekileyo kusebenzisa i-high-temperature calcined graphite particles okanye umxube we-graphite particles kunye ne-Al2O3 powder njengento ephakathi, kwaye uqhube ukutshisa umva phantsi kokukhusela i-hydrogen.

I-Decarburization kunye ne-backburning ngokuqhelekileyo zisebenzisa i-Al203 powder calcined kwiqondo lokushisa eliphezulu okanye umxube we-Al203 powder kunye nomgubo ococekileyo we-W njengento ephakathi, kunye ne-backburning yenziwa phantsi kokhuseleko lwe-hydrogen.

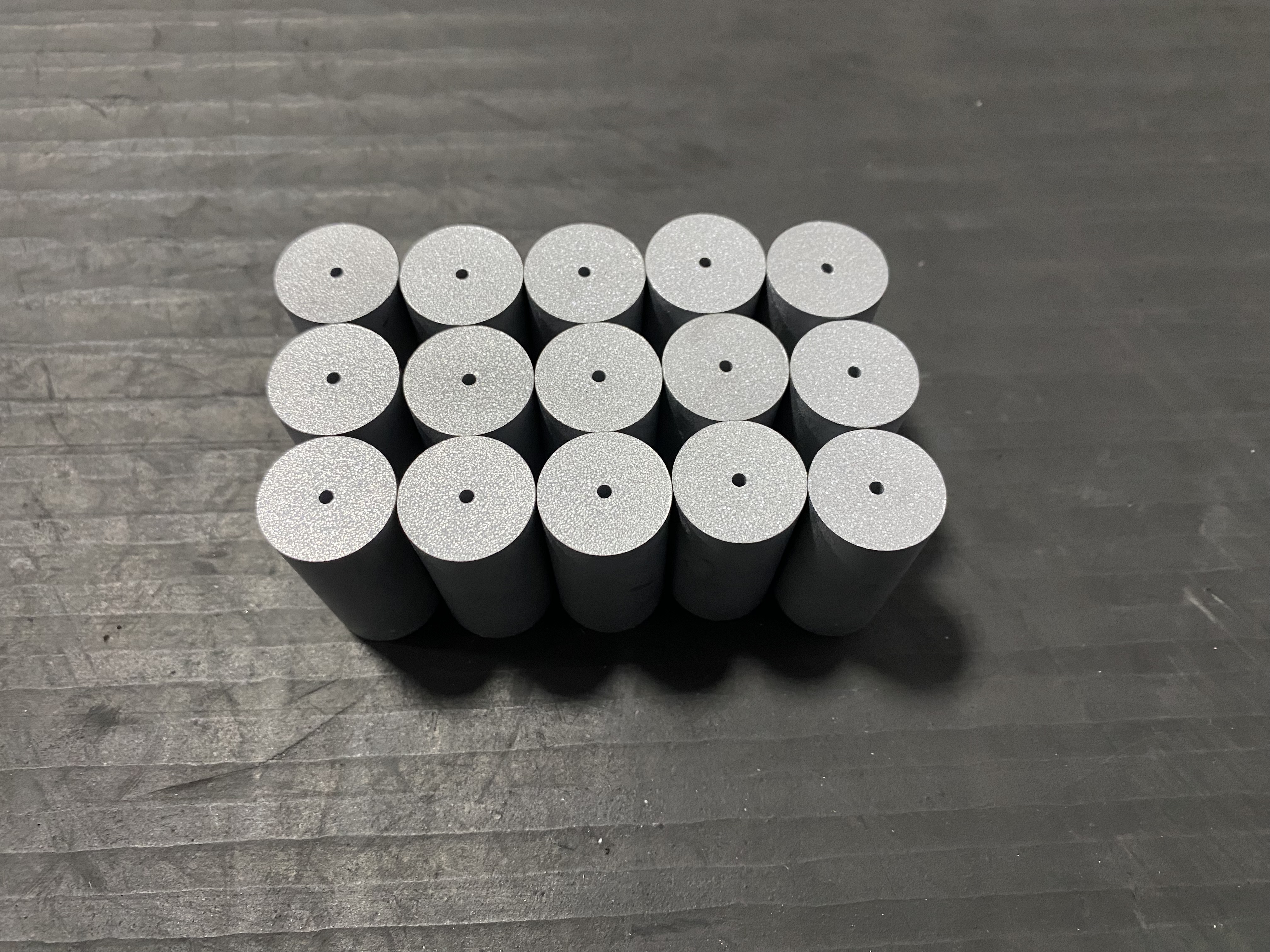

(2) I-porosity idlula umgangatho kwaye iyatshisa emva.Ukuba i-porosity ye-tungsten carbideiimveliso ze-sintered (iipores ezingekho nkulu kune-25 μm) zigqithise umgangatho, isithando somlilo soxinzelelo singasetyenziselwa ukucima uxinzelelo kuxinzelelo malunga ne-10MPa.Ubushushu be-sintering kufuneka bube malunga ne-20 ° C ngaphantsi kunobushushu bokuqala be-sintering yemveliso.Ukucutshungulwa kuxinzelelo oluphezulu usebenzisa i-isostatic eshushu yokucinezela kusebenza ngakumbi.

(3) Ukulungelelanisa.Ukubuyisela umva kwenziwa ngokufaka uxinzelelo kunye nokusebenzisa ukhuseleko lwe-hydrogen okanye i-vacuum state kwiqondo lobushushu elingaphezulu kancinci kunobushushu be-eutectic.Ubunzima obucinezelayo bunokulungelelaniswa okanye ubushushu bokulungiswa bunokwandiswa ngokwemeko yokulungiswa kwemveliso, kodwa ubushushu bokulungiswa akufanele bube ngaphezu kobushushu bokuqala be-sintering yemveliso.

Ixesha lokuposa: Jan-07-2024