1. Imiba yokucinga

I-carbide enesamenteyimathiriyeli yealloyi eyenziwe ngokudityaniswa kwekhabhide yentsimbi ekhanyelayo efana netungsten carbide (WC) umgubo kunye nentsimbi edibeneyo enjengomgubo wecobalt, ogama linguTungsten Carbide/Cemented Carbide ngesiNgesi, obushushu bayo buphezulu kunomgangatho wentsimbi yesantya esiphezulu. .

Isantya esiphezulu sentsimbi yenziwe ngenani elikhulu le-tungsten, i-molybdenum, i-chromium, i-cobalt, i-vanadium kunye nezinye izinto zentsimbi ephezulu ye-carbon high-alloy alloy, ikakhulukazi eyenziwe nge-carbide yensimbi (efana ne-tungsten carbide, i-molybdenum carbide okanye i-vanadium carbide) kunye nentsimbi. i-matrix, umxholo wekhabhoni we-0.7% -1.65%, inani elipheleleyo lezinto ze-alloying ukuya kwi-10% -25%, igama lesiNgesi le-Speed Speed Steels (HSS).

2, ukusebenza

Bobabini banobunzima obukhulu, amandla aphezulu, ubunzima obuhle, ubomvu-ubunzima, ukuxhatshazwa kokugqoka, ukuxhathisa ukushisa kunye nokusebenza kwenkqubo, njl., Kwaye zonke ezi mpawu ziya kuhluka ngenxa yamabanga ahlukeneyo.Ngokuqhelekileyo, ubunzima, ubomvu-bulukhuni, ukuxhathisa ukunxiba kunye nokumelana nobushushu be-carbide enesamente kungcono kunezo ze-HSS.

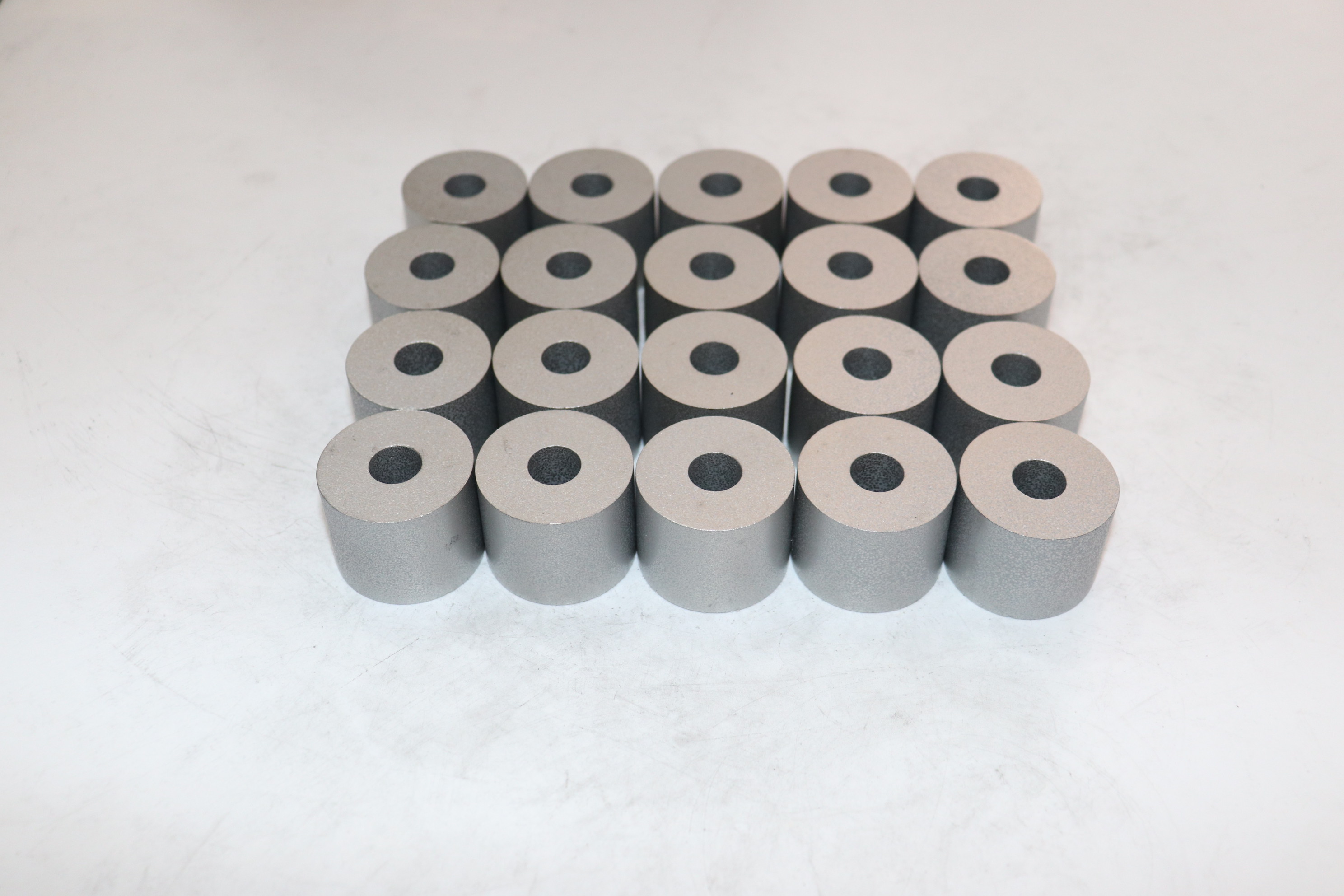

3, inkqubo yemveliso

Inkqubo yokuvelisa i-carbide enesamente ibandakanya ngokukodwa inkqubo ye-metallurgy engumgubo, iteknoloji yokubumba i-injection okanye inkqubo yoshicilelo lwe-3D.

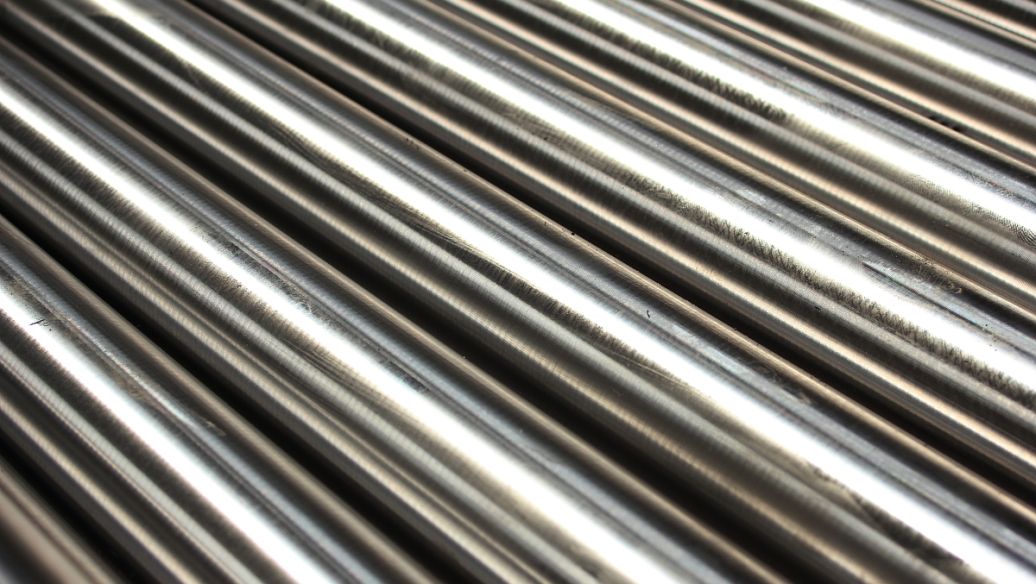

Iindlela zokuvelisa isantya esiphezulu sentsimbi zibandakanya iteknoloji yokuphosa yemveli, iteknoloji yokunyibilikisa i-electroslag, iteknoloji yomgubo wesinyithi kunye nobuchwepheshe bokubumba.

4, izicelo

Nangona bobabini banokwenza izixhobo, ukubumba okutshisayo komsebenzi kunye nokubumba okubandayo, baneempawu ezahlukeneyo.Izixhobo eziqhelekileyo ze-carbide zine-4 ukuya kwi-7 isantya esiphezulu sokusika kunye ne-5 kumaxesha angama-80 aphezulu ngaphezu kwezixhobo eziqhelekileyo ze-HSS.Ngokubhekiselele kwisixhobo, ubomi besixhobo se-carbide bungama-20 ukuya kuma-150 amaxesha aphakamileyo ngaphezu kwe-HSS tooling, umzekelo, ubomi bentloko eshushu kunye ne-extrusion die eyenziwe nge-3Cr2W8V yensimbi yi-0.5 yezigidi zezihlandlo, kunye nobomi bentloko eshushu kunye ne-extrusion. fa eyenziwe YG20 carbide yi 150,000 amaxesha.

Ixesha lokuposa: May-11-2023