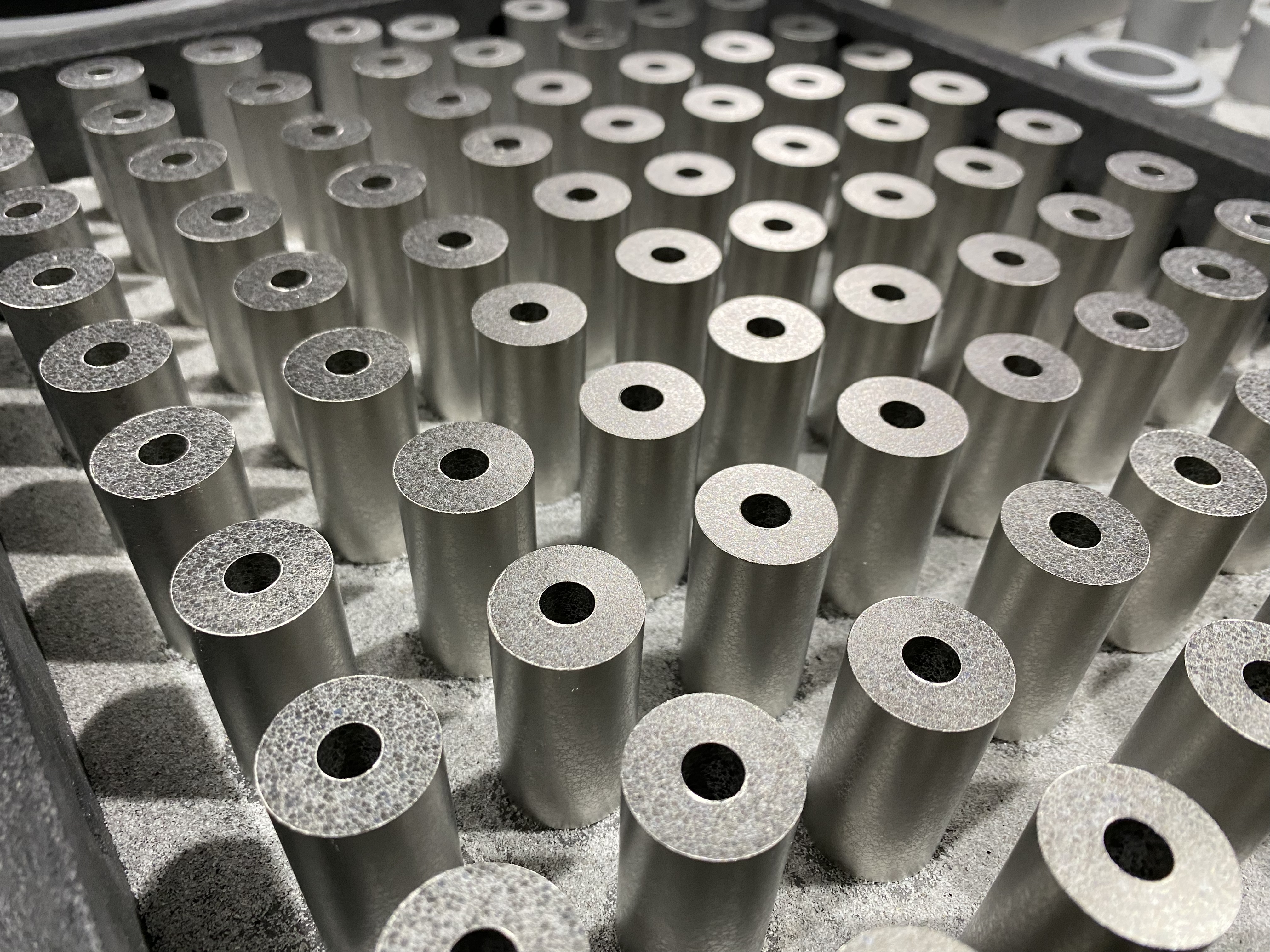

Intloko ebandayo iyafa kukubumba ukusetyenzwa kwentloko ebandayo, edla ngokwenziwa ngentsimbi enesantya esiphezulu, intsimbi yesixhobo sealloyi, ingxubevange eqinileyo kunye nezinye izinto.Isihloko esibandayo yinkqubo yokwenza isinyithi apho intonga yentsimbi icinezelwe kwaye ikhutshwe ngokufa okuphindaphindiweyo ukufezekisa ukumila okuthile kunye nenkqubo yokucubungula ubungakanani.Ukufa kwesihloko esibandayo ngokuqhelekileyo kuqulunqwe ngamacandelo amaninzi, kwaye imilo kunye nobukhulu becandelo ngalinye kuyahluka ngokwemveliso efunekayo.Iimveliso eziqhelekileyo ezibandayo zibandakanya iintambo ezahlukeneyo, i-pin shafts kunye namalungu amancinci amancinci.

Isihloko esibandayo se-tungsten carbide siyafa ngokubanzi senziwa yinkqubo yokucinezela ye-isostatic eshushu.Ukushisa kwe-sintering ikakhulu kuxhomekeke kwiimpawu ezibonakalayo kunye nokwakheka kweekhemikhali ze-tungsten carbide powder, kunye neemeko ze-sintering ezisetyenzisiweyo.Ngokubanzi, iqondo lobushushu le-sintering ye-tungsten carbide ebanda i-heading die ingaphezulu kwe-1500 ° C, kwaye ukhetho lobushushu obuthile lukwafuna ukuqwalasela iimfuno zoyilo kunye nenkqubo yokwenziwa kwefa.Ukuba ubushushu be-sintering buphezulu kakhulu, isakhiwo sokubumba siya kuphazamiseka, kwaye ukuba ukushisa kwe-sintering kuphantsi kakhulu, kuya kuba nzima ukufumana amandla okwaneleyo kunye nokumelana nokunxiba.Ke ngoko, ukukhethwa kobushushu be-sintering kufuneka kuthathelwe ingqalelo izinto ezahlukeneyo ngokupheleleyo ukuze kuqinisekiswe ukusebenza kakuhle kunye nobomi benkonzo ye-tungsten carbide heading ebandayo iyafa.

Ixesha lokuposa: May-21-2023