Iimpawu eziphambili zetungsten carbideekufuneka iqwalaselwe ekukhetheniimiqulu ye-tungsten carbidezezi zilandelayo:

Ukuchasana nokuqhekeka kwe-thermal

Ngokuqhelekileyo kwimiqulu enqabileyo ukuya kumandla, ukuchasana nokuqhekeka kwe-thermal njengeemfuno eziphambili;ezincinane 20-roll lokusila ukusebenza rolls ubunzima kuphela malunga 100 grams, lo gama ubunzima rolls inkxaso iipleyiti ipleyiti ebanzi idlule iitoni ezingama-200.Ukukhethwa kwemiqulu kuqala ngokweemfuno ezisisiseko zamandla e-mill kwi-rolls, ekhethiweyo ukuba iphathe ngokukhuselekileyo izinto eziphambili (amanqanaba ahlukeneyo esinyithi, intsimbi okanye intsimbi ekhandiweyo, njl. njl.).

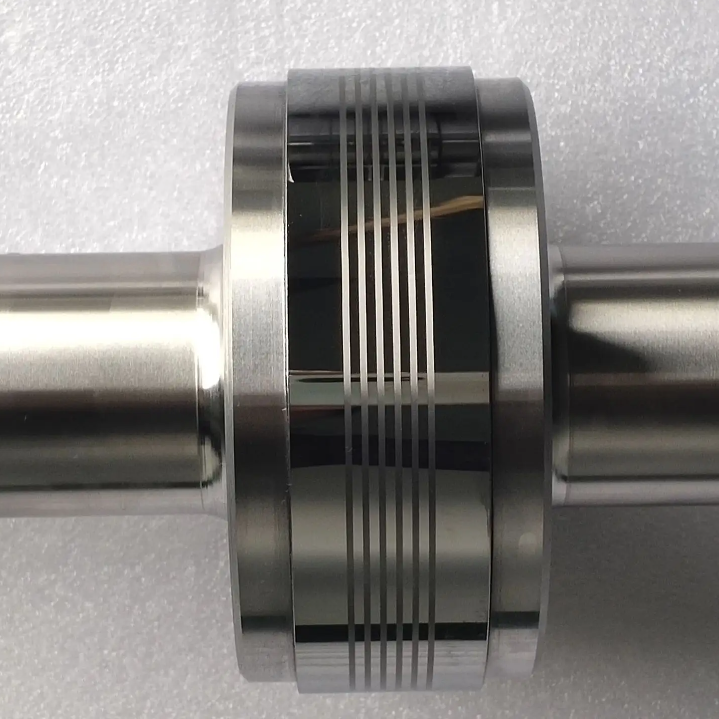

Ukuqina

Kwaye ukugqiba isantya somqulu uphezulu, ukuqengqeleka kwemveliso yokugqibela ukuba ibe nomgangatho othile womphezulu, ukuya kuyo ukuba lukhuni, ukuxhathisa ukunxiba, njl njl njengeemfuno eziphambili.Emva koko qwalasela imiqulu kufuneka isetyenziswe xa ukuchaswa kokugqoka.Ngenxa yokuba indlela yokunxiba yomqulu inzima kakhulu, kubandakanywa nefuthe loxinzelelo lomatshini, ifuthe lobushushu lokuqengqeleka, ukupholisa, isiphumo sekhemikhali sendawo yokuthambisa kunye nezinye iziphumo, akukho vavanyo lubanzi lokuxhathisa ukunxiba komqulu odibeneyo. isalathisi.Ekubeni ubunzima bulula ukulinganisa kwaye bunokubonakalisa ukunyanzeliswa kokugqoka phantsi kweemeko ezithile, i-curve ye-radial hardness ngokuqhelekileyo isetyenziselwa ukulinganisa isalathiso sokumelana nokunxiba kwemiqulu.

Ukuchasa impembelelo

Ukongezelela, kukho iimfuno ezikhethekileyo zemiqulu, njengomlinganiselo omkhulu woxinzelelo, imiqulu iyadingeka ukuba ibe nokuluma okunamandla kwikhono, ukumelana ngakumbi nempembelelo;

Ukuguda

Xa uqengqeleka iimveliso ezicacileyo ezinqabileyo, ukuqina, ukufana kweempawu zezicubu, ukuchaneka kokulungiswa kunye nokugqitywa komphezulu wemiqulu ziimfuno ezingqongqo;

Ukusika ukusebenza

Xa uqengqeleka amacandelo antsonkothileyo amacandelo, qwalasela kwakhona ukusebenza kokusika koluhlu olusebenzayo lomzimba we-roll.

Xa ukhetha imiqulu, ezinye iimfuno zentsebenzo yemiqulu zidla ngokuchasana, iindleko zokuthengwa nokugcinwa kwee-roll zixabisa kakhulu, ngoko ke iingenelo zobugcisa nezoqoqosho kunye nokungalungi kufuneka kulinganiswe ngokupheleleyo ukuze kugqitywe ukuba kusetyenziswe i-cast or forged, i-alloy okanye engeyiyo. i-alloy, imathiriyeli enye okanye imathiriyeli edibeneyo.

Ixesha lokuposa: May-23-2023