Masiqale ngezixhobo zokulungisa:

I-1, i-groove yangaphakathi, umngxuma, imicu yangaphakathi nangaphandle kunye nezinye izixhobo zokusebenza: kunye nezi mpawu zemilo, ngokuqhelekileyo sifuna ukusebenzisa isixhobo esikhethekileyo somatshini we-CNC - i-ceramic engraving kunye nomatshini wokugaya, esi sixhobo somatshini ngokoqobo sibonakala sinxulumene. ii-ceramics, enyanisweni, esi sixhobo somatshini sikwasebenza ekusetyenzweni kwe-carbide enesamente.Ngenxa yokuba xa kusetyenzwa i-carbide, uthuli oluninzi luya kuveliswa, kwaye umonakalo wolu thuli kwisixhobo somatshini kusenzima kakhulu.I-CNC yesiko inzima ukuxhathisa ezi zithuli zicolekileyo, ngaloo ndlela zikhokelela ngokulula ekugugileni kwesikrufu kunye namanye amalungu.Umkroli we-ceramic kunye nomatshini wokugaya unokusombulula le nto kakuhle, kuba umkrolo we-ceramic kunye nomatshini wokugaya unemilinganiselo yokukhusela egqibeleleyo, enokuthi ihlukanise kakuhle i-carbide powder kwizinto ezichanekileyo.

2、 Ukulungisa izixhobo zeenqwelomoya kunye namanyathelo: Xa kusetyenzwa iinqwelomoya ezinkulu kunye namanyathelo phezulucarbideizinto eziphathekayo, kungcono ukusebenzisa i-grinders yomhlaba, enomsebenzi ophezulu wokuchaneka kunye nokusebenza kakuhle.

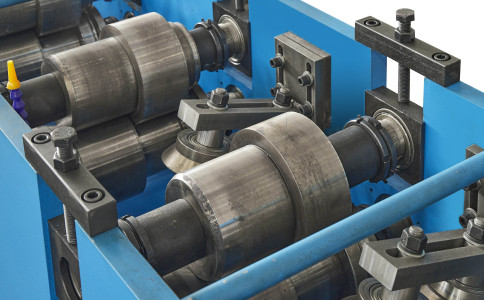

3, Ukulungisa izixhobo zesangqa sangaphandle: umatshini wokusila wangaphandle, umatshini wokusila ongenaziko, njl.

iindlela Machining ofi-carbide enesamente:

I-1, Ukwenziwa kweentambo zangaphakathi nangaphandle: Ukulungiswa kwentambo ye-carbide ene-cemented kufuneka kuqhutywe ngokugaya intambo, kungekhona ngokuthe ngqo kwimpompo.

2, Ukusetyenzwa kwe-groove yangaphakathi: intonga yokusila idayimani kufuneka isetyenziswe, kwaye inani le-undercutting lilawulwa malunga ne-2-3 iingcingo ngexesha ngalinye, ekufuneka lilungelelaniswe ngokuhambelana neenzuzo kunye nokungalunganga kwentonga yokusila idayimani.

3, Ukukhutshwa kombane ngomatshini (kucingo, ucingo olucothayo, ukusetyenzwa kocingo oluhamba ngokukhawuleza)

I-4, i-Welding processing: i-welding yobhedu, i-welding processing yesilivere.

I-5, i-grinding processing: i-centerless grinding, i-grinding yangaphakathi, i-plane yokusila, isixhobo sokusila, ivili lokusila elisetyenzisiweyo ngokuqhelekileyo ivili lokusila idayimani, kuxhomekeke kwiimfuno zenkqubo yokukhetha.

I-6, ukusetyenzwa kweLaser: ukusika kwe-laser kunye nokwenza, ukubethelwa, kodwa ubukhulu bokusikwa bubotshelelwe ngamandla omatshini we-laser.

Ixesha lokuposa: Jun-22-2023