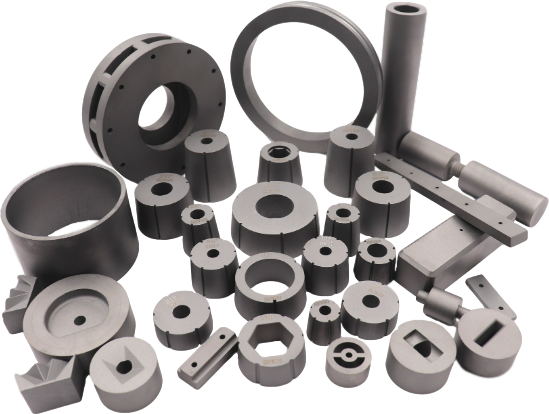

Njengoko igama lamazinyo e-industrial carbide, ininzi yalabo abayisebenzisayo abazi ukuba i-carbide yenziwa njani kwaye yintoni umehluko kwinkqubo yokuvelisa, eqinisweni, ukuveliswa kwe-carbide kuhambelana nokusetyenziswa kwayo kwendalo.Umzekelo, i-carbide yokwembiwa kwemigodi, i-carbide yokomba amatye, carbideizixhobo ezijikayo, njl.njl zonke zisekwe kusetyenziso lokusingqongileyo.Kukho kwakhona umzekelo i-corrosion resistant carbide njalo njalo.

Yenziwa njani iCemented Carbide?Ithini inkqubo yayo yokuvelisa?

Inkqubo yokuvelisa i-carbide ene-cemented ngokuqhelekileyo ngolu hlobo lulandelayo: i-refractory metal hard compounds (i-tungsten carbide, i-tantalum carbide, njl.), i-bonding metal (cobalt powder okanye i-nickel powder) kunye nenani elincinci lezongezo (i-stearic acid okanye i-esomin) zixutywe kwaye umhlaba kwi-hexane medium yokusila, kwaye i-slurry ye-wax yeparafini yongezwa, emva koko i-vacuum yomisiwe (okanye i-spray yomisiwe), ihlungwe, ihlanjululwe, kwaye yenziwe kwizinto ezixutywe;izinto ezixutywe zichongiwe kwaye zifanelekile, kwaye emva kokuchaneka kwezinto ezixubileyo zichongiwe kwaye zifanelekile, emva koko zicinezelwe ukwenza i-billet ephezulu yokushicilela;I-billet ecinezelweyo ifakwe i-vacuum dewaxing okanye i-low-pressure sintering ukwenzai-carbide enesamente.

Sintering umgaqo

Inkqubo ye-vacuum sintering iqhutyelwa ngokufudumeza phantsi kweemeko ze-vacuum, ezilungele ukuphelisa ukungcola, ukuphucula ukucoceka kwe-sintering atmosphere, ukuphucula ukumanzi kwesigaba sokubambisana kunye nokukhuthaza ukusabela.Ibillet ecinezelweyo ifudunyezwa kwi-vacuum sintering atmosphere, kwaye njengoko iqondo lobushushu linyuka kwaye lifikelela kubushushu bobushushu, liyabaleka kwibillet ecinezelweyo kwaye ligcinwe ixesha elaneleyo kuxinzelelo oluyinxenye lomphunga weparafini ongaphantsi kobo bushushu, kunye neparafini. iyakhutshwa kwibillet* ecinezelweyo ize ibuyiselwe, kwaye ibhilethi ecinezelweyo iyahlanjululwa.Njengoko iqondo lokushisa linyuka ngakumbi, i-billet ichithwa kwaye ihlanjululwe ngakumbi, kwaye i-slid-phase sintering ilandela.Kwinkqubo ye-sintering yesigaba esiqinileyo, ii-athomu (okanye ii-athomu) zecandelo ngalinye kumzimba odibeneyo zisasazeka, indawo yokudibanisa i-particle iyanda, umgama phakathi kwamasuntswana uyancipha, umzimba odibeneyo uyancipha kwaye uqiniswe ngakumbi.Xa ubushushu busondele kwindawo yokunyibilika yesigaba esibotshiweyo, isigaba esibotshiweyo siqala ukuhamba kweplastiki, kwaye xa ubushushu besigaba solwelo bufikelelwe, umzimba we-sintered uvelisa isigaba solwelo kunye nesigaba solwelo sintering.

Kwinkqubo yesigaba solwelo sintering, umaleko wesigaba solwelo ubonakala kwi-carbide surface, kunye necarbideiinqununu zichithwa kwisigaba sokubambisana ngokusasazwa ukwenza i-eutectic, kunye neengqungquthela ze-carbide ziphinde zikhule kwaye zikhule ngobukhulu ngesigaba solwelo, ukwenzela ukuba iinqununu ze-carbide ezikufutshane zidibaniswe ngokusondeleyo, kwaye umzimba odibeneyo uyancipha ngakumbi kwaye ugxininise ngokukhawuleza.Umzimba we-sintered uyancipha ngakumbi kwaye uxinene ngokukhawuleza.Igcinwe kwiqondo lokushisa elingaphezulu kweqondo lokushisa le-sintering yesigaba solwelo ixesha elithile ukwenzela ukuvumela inkqubo ye-sintering ukuba iqhube ngokupheleleyo, kwaye ipholile.

Kuyo yonke inkqubo ye-sintering, umzimba we-sintered ugxininiswe kufuphi ne-non-porosity, kwaye uchungechunge lweempembelelo ze-physicochemical kunye nohlengahlengiso lombutho ziveliswa, okukhokelela ekubunjweni kwe-carbide eshinyeneyo, ene-cemented kunye nokwakheka kweekhemikhali ezithile, iipropati zomzimba kunye noomatshini, kwaye Ubume bombutho.

Ixesha lokuposa: Jun-29-2023