Iialloyi eziqinileyo zeWC-Co zinokuguquguquka kakuhle kwi-microwave.Ngexesha lenkqubo ye-sintering, iindlela zokulahleka ezisebenza kwindawo yobushushu obuphantsi ubukhulu becala yilahleko yokuphumla kwepolarization kunye nokulahleka kwemagnethi, ngelixa kwindawo yobushushu obuphezulu ialloy ifunxa amandla e-microwave.Ikakhulu ngendlela yokulahleka kwe-dielectric kunye nokulahleka kwe-conductivity.

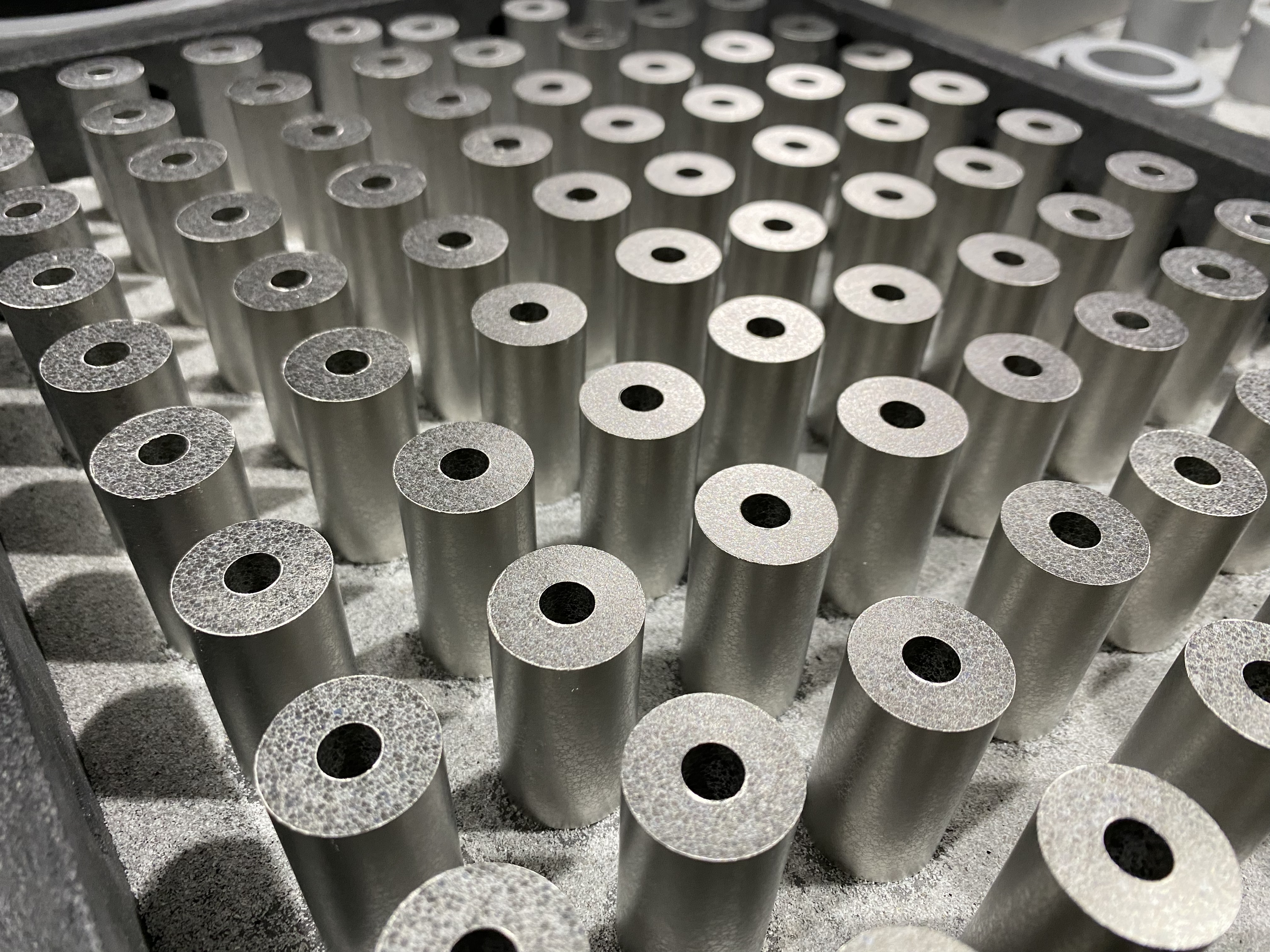

Iingxubevangekunye nokongezwa kwe-0.4% ye-VC kunye ne-0.2% ye-Cr3C2 (i-fraction mass) njengezinto ezincedisayo ezinomsebenzi ongcono kakhulu;Ukusetyenziswa kwe-vacuum microwave sintering kuphucula kakhulu ukusebenza kwe-alloy.Ukusebenzisa i-multi-cavity microwave sinteringWC-8Co, ifakwe kwi-1400 ° C ngaphandle kokugcinwa kobushushu.Ubuninzi bunokufikelela kwi-14.71g / cm, iI-HRA ifikelela90.3, kwaye isakhiwo siyafana.

Itekhnoloji ye-Microwave sintering ingasetyenziselwa ukulungisa iicermets ze-ultra-fine kunye neenkozo ezintle, ukwakheka okufanayo kunye nokusebenza okugqwesileyo.Njengoko ukushisa kwe-sintering kwanda, ukucutha, ukuxinana, amandla okuguquguquka kunye nobunzima be-ultra-fine cermets kuqala ukwanda kwaye emva koko kuyancipha, ngexabiso eliphezulu elibonakala kwi-1500 ° C;Inkqubo efanelekileyo ye-microwave sintering ye-ultra-fine cermets Emva kokugcinwa kwi-1500 ° C kangangemizuzu engama-30, amandla okuguquguquka kunye nobunzima bexabiso yi-1547MPa kunye ne-90.6HRA ngokulandelelanayo, eyonyuswe ngama-24.0% kunye ne-0.7% ngokulandelelanayo xa kuthelekiswa ne-sintering eqhelekileyo.

Ixesha lokuposa: Jan-03-2024