I-15% ye-Cobalt YG15 ye-Tungsten Carbide i-Cold Heading iFa ngenxa yomatshini wentloko obandayo

I-HengRui Cemented carbide ngumvelisi oqeqeshiweyo we-carbide enesamente e-China.Inkampani izibophelele kuphando kunye nophuhliso, ukuveliswa kunye nokuthengiswa kwezinto ezintsha kunye neemveliso ezintsha ze-carbide enesamente.Ukuza kuthi ga ngoku siye saphuhlisa uthotho lweemveliso eziphambili ezibandakanya iintsimbi ze-carbide, iipleyiti, iimbumba, idis cutter, izixhobo zemigodi kunye nabanye abathungi abakhethekileyo.Yintoni ngakumbi iimveliso zethu zinikwe isiqinisekiso ISO9001:2008.Awunakukhathazeka malunga nomgangatho wemveliso yethu.

| Tungsten Carbide Cold Forging/heading Dies | ||||

| Amabanga | Ukuxinana | TRS | Ukuqina | Ukusebenza kunye nesicelo esicetyiswayo |

| g/cm³ | MPa | HRA | ||

| YG11 | 14.4 | ≥3000 | 88.5 | Ukubumba okanye ukunyathela kufa ngenxa yomgubo wentsimbi kunye nomgubo ongeyontsimbi. |

| YG15 | 14 | ≥3400 | 87.5 | Ukwenza umzobo wokwenza umzobo uyafa ngeetyhubhu zentsimbi kunye neentonga phantsi komlinganiselo wokuxinezeleka okuphezulu;ukubetha, ukunyathela, ukwenza izixhobo phantsi koxinzelelo olukhulu. |

| YG20 | 13.5 | ≥3800 | 85.5 | Ukwenziwa kwesitampu seendawo zokubukela, iipleyiti zasentwasahlobo zezixhobo zomculo, iijagi zebhetri, iibhola zentsimbi ezinobungakanani obuncinci, izikrufu, izikrufu. |

| YG15C | 14 | ≥4000 | 86.5 | Kwimibhobho ye-oyile ye-cone, sika phakathi amatye athambileyo naqinile;ukukrazula kunye nokusika umthi omkhenkce, umthi othambileyo kunye neenkuni zokuqala. |

| YG16C | 13.9 | ≥3500 | 85.5 | Ukunyangwa kwempembelelo kuyafa. |

| YG18C | 13.7 | ≥3600 | 84.5 | Ukuchaneka kwempembelelo yokunyathela kuyafa, ukubunjwa kwe-hot-press kuyafa kunye neerola. |

| YG20C | 13.5 | ≥3800 | 83.5 | Ifa ngenxa yokunganyangeki okanye ukumelana nempembelelo kwisicelo. |

| YG22C | 13.3 | ≥4000 | 83 | Ukwenziwa kwamandongomane kuyafa kwaye ukuxhathisa kwempembelelo ephezulu kuyafa. |

| YG25C | 13.1 | ≥4250 | 82.5 | Intloko yebholithi engatyiwayo iyafa kunye neerola. |

1. Iilebhu zokuhlola oomatshini kunye neekhemikhali ukulawula umgangatho

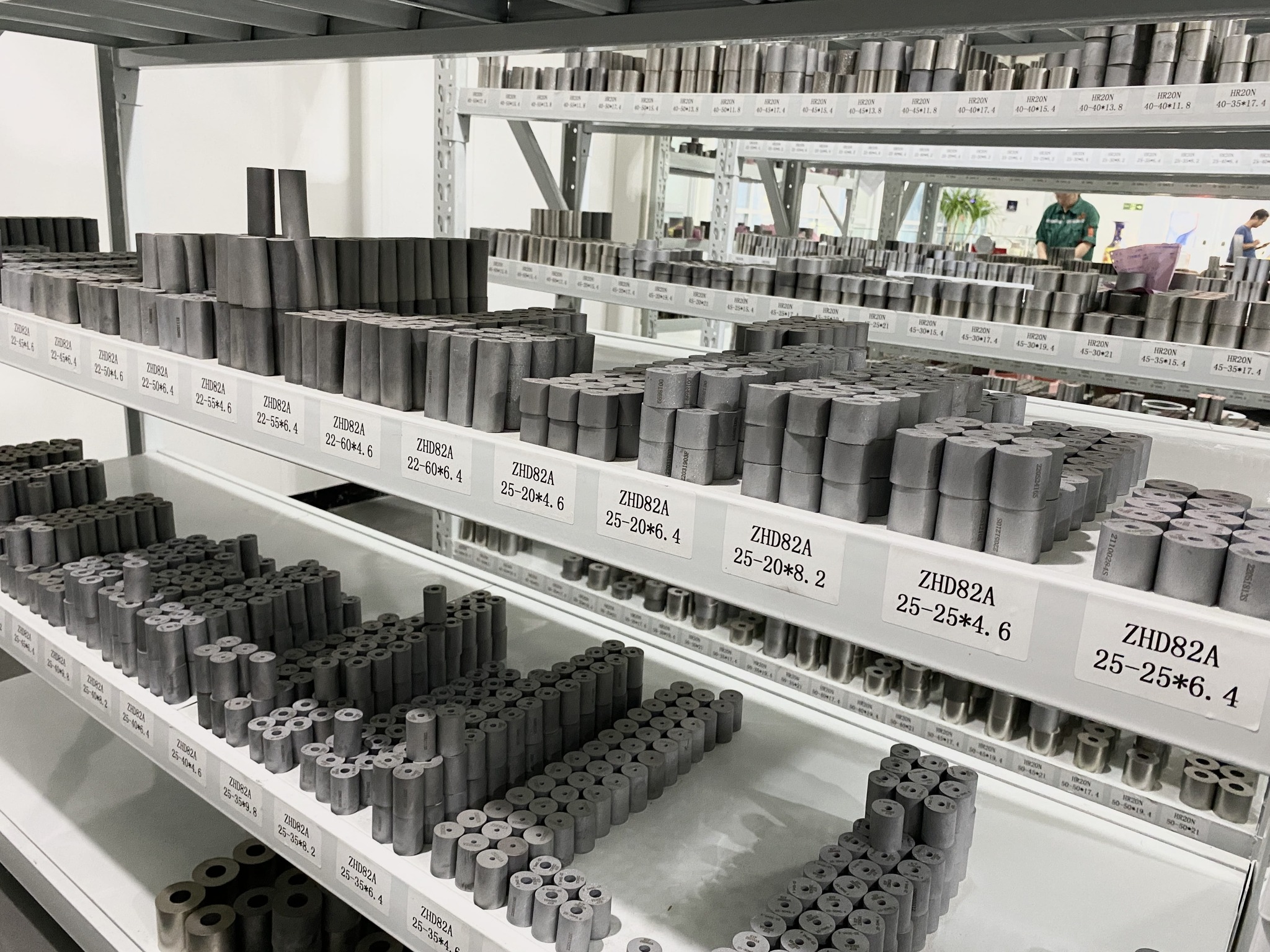

2. Uluhlu olupheleleyo lweentlobo ezikhoyo, ziyahlangabezana neemfuno ezahlukeneyo zabathengi.

3. Umgangatho ozinzileyo, ixesha elifutshane lokuhambisa ngexabiso elikhuphisanayo

4. Ukuchaneka okuphezulu kunye nobomi benkonzo ende

5. Iphakheji yobungcali, ukukhusela iimveliso kumonakalo

Ungqamaniso lweMathiriyeli→Ukugaya iBhola eManzi→I-WC exubeneyo kunye naMandla eCobalt→Ukucinezela→Iziko zokuJonga zeHIP→Ukuchongwa kweQC→Ukupakisha

1. Siya kuzama konke okusemandleni ethu ukuphendula isicelo sabathengi bethu kwiiyure ezingama-24.

2. Siya kugcina unxibelelwano olusebenzayo nolusebenzayo kunye nabathengi bethu.

3. Sinikezela ngolawulo lomgangatho wokuqala kunye neenkonzo emva kokuthengisa.

Siya kuzisa umthwalo oveliswe ngobunzima phakathi kweentsuku ezingama-30 emva kwentlawulo ephantsi, ngelixa, ukuba kukho izicelo ze-soecific ngexesha lokuhanjiswa.Sinokwenza utshintsho ngokwesicelo sabathengi, ngoko ke ixesha elifutshane lokuhambisa lifumaneka ngokupheleleyo.

Ngokuqhelekileyo i-30% T / T kwangaphambili, ibhalansi ye-70% ngaphambi kokunikezelwa.Kananjalo inokutshintsha ngokwesicelo sabathengi.

Senza amacandelo ngokweemilo ezahlukeneyo kunye nobukhulu ukuze angqinelane neemfuno zabathengi bethu ngokuthe ngqo, nokuba bafuna iibhloko okanye amaphepha, iisilinda, iibheringi, iingcebiso okanye amazinyo.