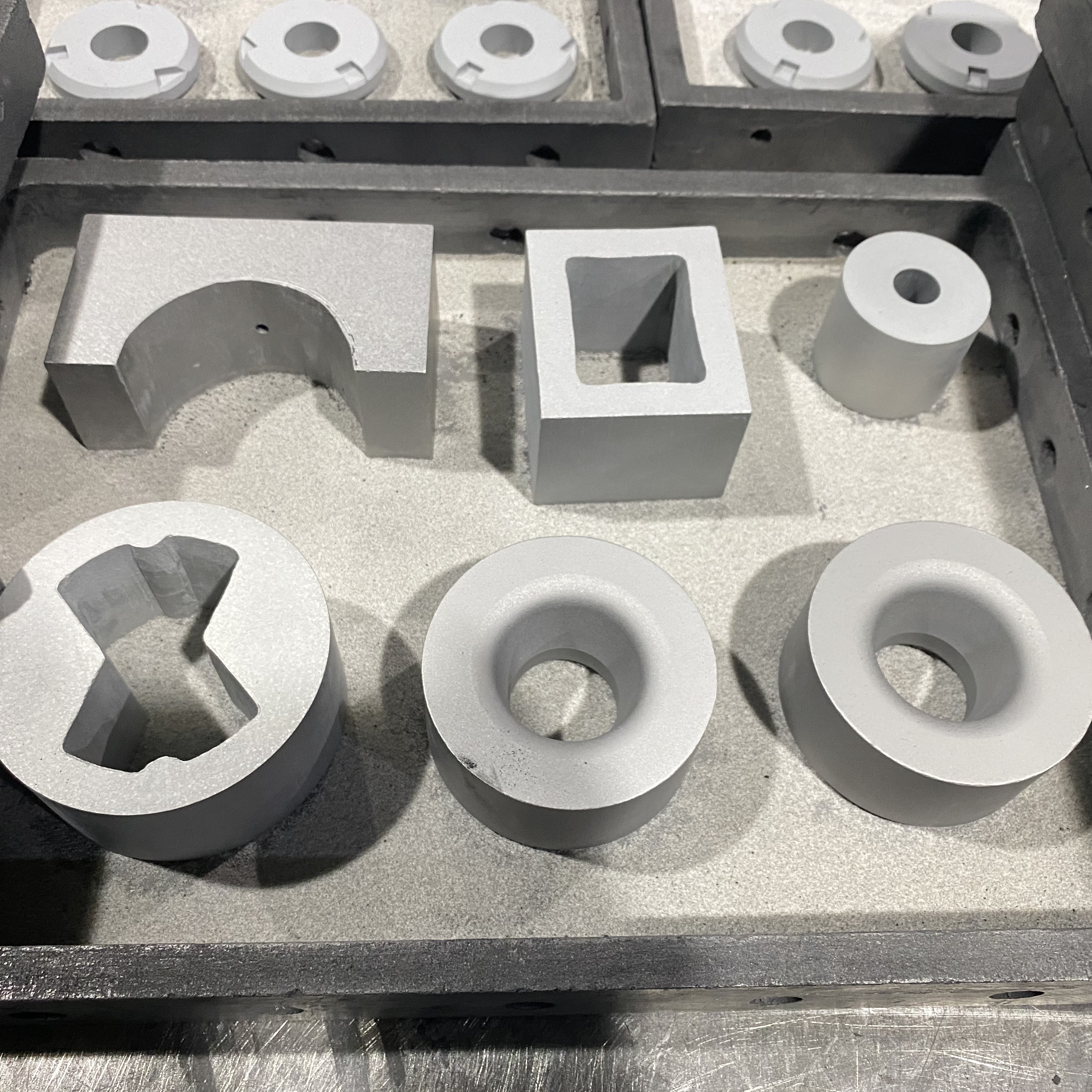

Ukuculwa kwei-carbide enesamenteIsigaba solwelo sintering, oko kukuthi, isigaba sokudibanisa kwakhona sikwinqanaba lolwelo.Iibhilithi ezicinezelweyo zifudunyezwa kwi-1350 ° C-1600 ° C kwisithando somlilo.I-shrinkage yomgca we-billet ecinezelekileyo ngexesha le-sintering malunga ne-18% kwaye i-volume shrinkage ijikeleze i-50%.Ixabiso elichanekileyo le-shrinkage lixhomekeke kubukhulu be-particle ye powder kunye nokubunjwa kwe-alloy.

Sintering ofi-carbide enesamenteyinkqubo entsonkothileyo ye-physicochemical, ebandakanya ukususwa kwe-plasticizer, i-degassing, i-slid phase sintering, i-liquid phase sintering, i-alloying, i- densification, i-dissolution precipitation kunye nezinye iinkqubo.I-billet ecinezelekileyo i-sintered phantsi kweemeko ezithile zokwenza imveliso enekhemikhali ethile, isakhiwo, iipropati kunye nemilo kunye nobukhulu.Ezi meko zenkqubo ziyahluka kakhulu ngokuxhomekeke kwiyunithi ye-sintering.

I-cemented carbide vacuum sintering yinkqubo apho i-sintering yenziwa ngaphantsi kwe-1 atm (1 atm = 101325 Pa).I-Sintering phantsi kweemeko ze-vacuum kunciphisa kakhulu isithintelo soxinaniso ngegesi ebhedleleyo kumphezulu womgubo kunye negesi kwimibhobho evaliweyo, enceda inkqubo yokusasazwa kunye noxinaniso, ithintela ukusabela phakathi kwesinyithi kunye nezinye izinto ezisemoyeni ngexesha inkqubo ye-sintering, kwaye inokuphucula ngokubonakalayo ukumanzi kwesigaba se-viscous se-liquid kunye nesigaba esinzima, kodwa i-vacuum sintering kufuneka ithathele ingqalelo ukuthintela ilahleko yokuphuphuma kwe-cobalt.I-vacuum sintering inokohlulwa ngokubanzi ibe ngamanqanaba amane, oko kukuthi, inqanaba lokususa iplastizer, inqanaba langaphambi kwe-sintering, inqanaba lobushushu obuphezulu kunye nenqanaba lokupholisa.

Inqanaba lokususa iplasticizer liqala kubushushu begumbi kwaye linyuke ukuya kuma 200°C.I-gas adsorbed ebusweni be-powder particles kwi-billet ihlukaniswe ukusuka kwindawo yeengqungquthela phantsi kwesenzo sokushisa kwaye ibalekela kwi-billet ngokuqhubekayo.I-plasticizer kwi-billet iyatshisa kwaye ibalekela kwi-billet.Ukugcina inqanaba eliphezulu le-vacuum kunceda ukukhululwa kunye nokuphunyuka kweegesi.Iindidi ezahlukeneyo zeplastiki zineempawu ezahlukeneyo xa ziphantsi kobushushu, ngoko ke inkqubo yokususa iplastiki kufuneka iphuhliswe ngokwemeko ethile.

Inkqubo yokususwa kwePlastiki kufuneka imiselwe ngokweemeko ezithile zovavanyo.Ubushushu beplastiki yegesi ngokubanzi bungaphantsi kwama-550 ℃.

Isigaba sangaphambili se-sintering sibhekisela kwiqondo lokushisa eliphezulu lokutshisa ngaphambi kokuba i-sintering, ukwenzela ukuba i-oksijini yekhemikhali kwi-particle powder kunye nokunciphisa i-carbon reaction reaction ukuvelisa i-carbon monoxide gas eshiya i-billet ye-press, ukuba le gesi ayikwazi ukukhutshwa xa isigaba solwelo sibonakala, iya kuba yintsalela ye-pore evaliweyo kwi-alloy, nokuba i-pressurized sintering, kunzima ukuyiphelisa.Ngakolunye uhlangothi, ubukho be-oxidation buya kuchaphazela kakhulu ukumanzi kwesigaba se-liquid kwisigaba esinzima kwaye ekugqibeleni kuchaphazele inkqubo yoxinaniso lwe-carbide ene-cemented.Ngaphambi kokuba kuvele isigaba solwelo, kufuneka sisuswe ngokwaneleyo kwaye kusetyenziswe eyona vacuum iphezulu.

Ukushisa kwe-sintering kunye nexesha le-sintering ziyimilinganiselo yenkqubo ebalulekileyo yoxinaniso lwe-billet, ukubunjwa kwesakhiwo esilinganayo kunye nokufumana iipropati ezifunekayo.Ukushisa kwe-sintering kunye nexesha le-sintering lixhomekeke ekubunjweni kwe-alloy, ubungakanani bepowder, amandla okugaya umxube kunye nezinye izinto, kwaye zilawulwa yilo lonke uyilo lwezinto.

Ixesha lokuposa: Jun-08-2023